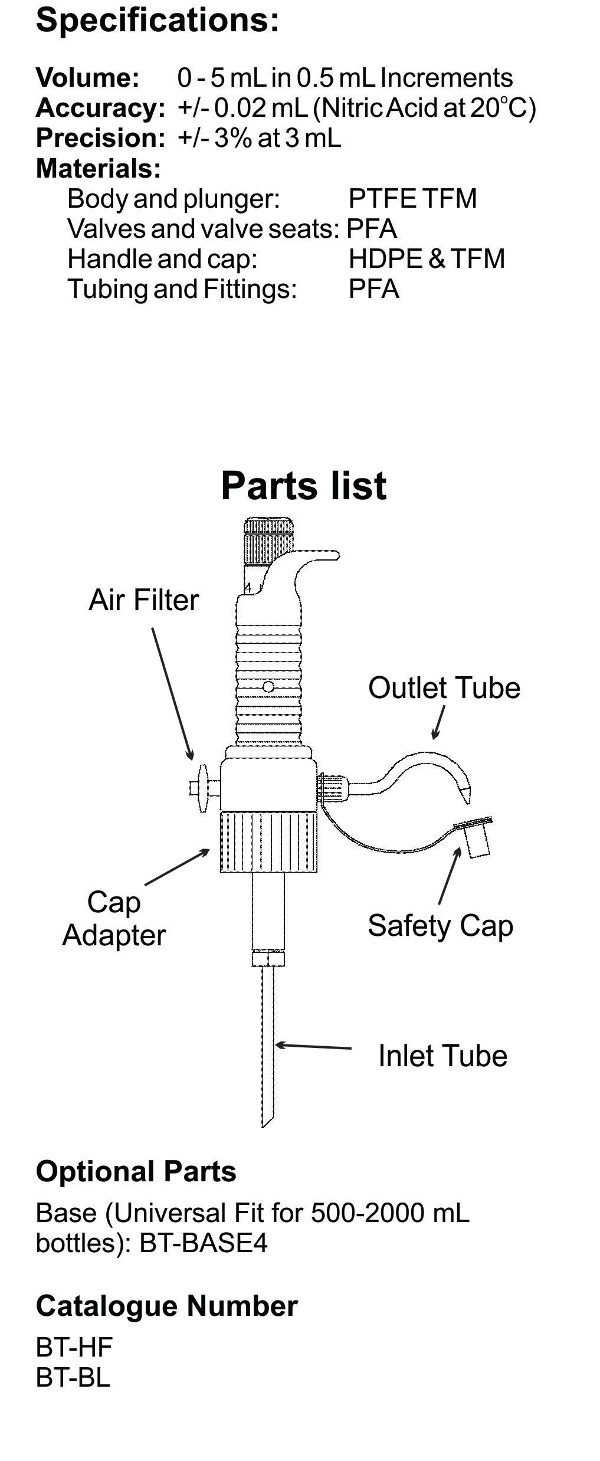

Bottle-Top Acid Dispenser shown with the optional support base (BT-BASE4)

Dispensing small volumes of high purity acids from a bottle safely and reliably, without contamination or waste has always been a challenge. Pouring introduces the possibility of contamination each time the bottle is opened and invariably leads to waste.

Traditional bottle-top pump dispensers are more convenient, safer and cut down on wasted product. However some of the materials used in construction such as glass and ceramics will leach unacceptably high levels of some elements. In addition, traditional dispensers cannot be used with Hydrofluoric Acid.

The new SEASTAR™ Bottle-Top Dispensers were developed to combine the convenience of a traditional pump dispenser with the chemical compatibility and high purity afforded by Fluoropolymers.

All wetted parts in the SEASTAR™ Bottle-Top Dispensers are constructed of Fluoropolymer PFA or high purity TFM (a modified PTFE) including check valves and seals. The result is a dispenser that can be used with high purity concentrated acid.

Two models are available:

SEASTAR™ HF Bottle-Top Dispenser: For applications which require the chemical resistance of fluoropolymers, such as ACS or Technical grade acids (including Hydrofluoric Acid). These dispensers are calibrated and mechanically tested to ensure each unit meets the required volume, precision and accuracy requirements.

BASELINE® Bottle-Top Dispenser: All wetted parts of the BASELINE® model have been extensively acid pre-cleaned. These pre-cleaned parts are assembled in SEASTAR™’s trace metal clean room. Once assembled, the dispenser is then calibrated and mechanically tested to ensure the unit meets the required volume, precision and accuracy requirements. Following calibration, the unit is then filled with SEASTAR™’s high purity Nitric Acid for further cleaning and mechanical testing. The unit is then thoroughly rinsed with SEASTAR™’s high purity water to remove all residual acid, and then packaged in SEASTAR™’s trace metal clean room. This process ensures that the unit performs optimally upon receipt.